Maintenance experience of injection molding machine

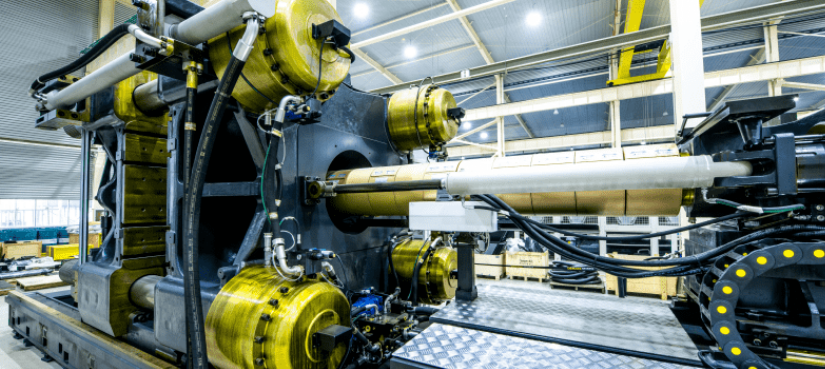

Injection molding machine is a mechanical, electronic control, hydraulic integration crystallization, electrical complex, oil pressure pipeline crossing buildings, all kinds of products since 80s, fault phenomenon is all sorts of strange things, each are not identical, especially imported injection molding machine, the price is expensive, each about tens of thousands to hundreds of thousands of dollars. Large shot weight injection machine has only tens of thousands of components, if one component fails, it will cause the injection molding machine is not a normal phenomenon, and wire connection, a little carelessness will be a problem, coupled with the large injection molding machine used in large volume, constant temperature, injection molding workshop conditions the environmental impact is likely to cause fault. To this end, the import of injection moulding machine "maintenance difficult" problems placed in front of us.

With so many injection machines introduced, how can we quickly find out the faults and hidden dangers and eliminate them in time? How can this expensive equipment be repaired? I think we should have a high sense of responsibility; Second, we should word hard to master CNC hydraulic technology, practical injection molding technology of injection machine more than 10 years maintenance experts think to see more, ask more and more, think more, and more practice, gradually improve their technical level and maintenance ability, can adapt to all kinds of complicated situation, solve the difficult problem of fixed injection molding machine.

First, watch more.

1). To see the injection molding machine electronic circuit data to see, to understand the characteristics and functions of all kinds of injection molding machine, electronic circuit system and PLC. To understand the alarm electronic circuit system and the action of injection machine programming. To understand the control panel of the plastic injection moulding machine operation and the contents of the menu, see how often a lot of data? I think the main focus, clarify the sequence of events, focusing on the basic understanding of composition and structure of injection machine controller, control block diagram. The rest can be "read" and read through, but each part should be understand and mastered with emphasis. As the preform injection moulding machine controller internal wiring diagram is quite complex and manufacturers are not provided. Therefore, there is no need to clarify in detail. We should focus on the function of each part, the function of each board, the direction of the interface, the meaning of the LED lamp and so on. Now bottle preform injection molding machine controller model is many, update fast, different injection machine manufacturers, different models are often very different. We should understand there commonness and individuality.

2). To see the electrical diagram for each electrical components, such as: contactor, relay, time relay and PC, PLC input and output, in the electrical diagram are indicated.

3). We should look at the hydraulic chart and in-depth digestion of the injection molding machine, hydraulic drawings, to clear its role and the ins and outs. And on the drawings indicate one by one, such as the lock mode which solenoid valve action? What are the corresponding PC, PLC outputs and inputs? Write down the diagram so that the pole moves from electrical to mechanical.

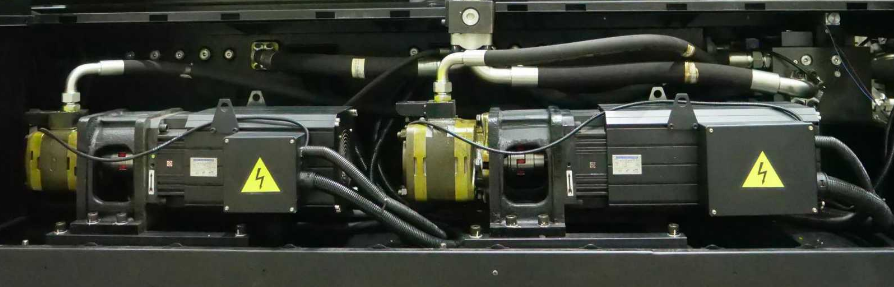

At the same time, especially for electric machine, more closely related to focus on understanding, now the injection molding machine using the electro-hydraulic proportional technique, we should focus on understanding the role and function, especially to understand the adjusting method and adjusting data, pressure proportional valve and pump current corresponding to the static and dynamic, then to master a variety of skills, ability to solve problems.

Two, ask more.

1). Ask more injection moulding machine experts, if you can have training opportunities or injection molding machine experts to your factory installation and commissioning of injection machines, you had better have the opportunity to participate. This is one of the best opportunities for learning, because you can get a lot of debugging methods and skills, do not understand, we must make it clear. Through this period of time, there will be a great harvest and access to a lot of internal information and manuals. When the injection machine is put into production, it should also keep close contact with the experts involved in the injection molding machine. By fax, email, get asked machine manufacturers to solve difficult fault injection moulding machine further solutions and relevant materials, it is very useful, and the controller agent manufacturers should also maintain a good relationship, ask for more, also can get the further information and the relevant spare parts, you can also have the opportunity to participate in the injection machine factory.

2). After the failure, ask a little detail, the whole process to the injection molding machine fault (beginning, middle, end), have what alarm number, when operating over what elements touched what, to what, how the external environment? To master in the full investigation site based on the first-hand materials, the problem of fault correctly listed, in fact have solved the problem of solving the half, the analysis, injection moulding machine operator for experienced skilled, they are familiar with the injection machine operation program, familiar with common injection machine is very understanding, close cooperate with them, is very beneficial for rapid troubleshooting.

3). Please ask other maintenance personnel, when other maintenance personnel in the maintenance of injection moulding machine, and you did not go, when they com back, also should ask more, what happened just now? How did re rule it out? Ask him to introduce his method of elimination. This is also a good opportunity to learn. Learn the correct troubleshooting skills and methods of others, especially to veteran experienced maintenance personnel. Learn their skills and improve your knowledge and level.

Three, remember more.

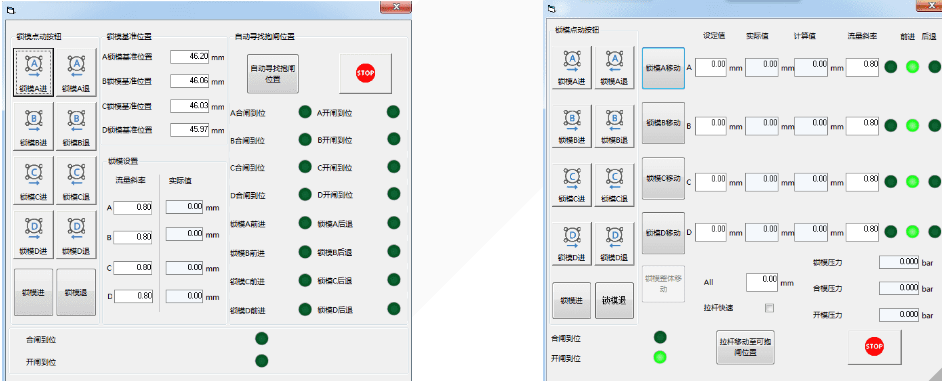

1). To record all the parameters, focus on the injection machine after adjustment of a variety of related parameters, such as injection molding machine pressure parameters, injection moulding machine speed parameters, injection molding machine motor current, voltage, speed and other data, it is very useful for repairing injection machines.

Also remember state relays and other electrical cabinet in power and formal processing time and PC, PLC all the input and output of LED light emitting diodes (light and dark, shinning) or recorded on the screen of PC, PLC (input) and (output) is 0 1 or so, recorded for later analysis and judge the fault of great benefit.

2). To record the hydraulic system of the hydraulic system in the same state record of formal processing or not when processing all kinds of pressure gauge pressure, suction state of electromagnetic valve off, this is also a great help for the level of injection moulding machine function is normal or not, the record of the static and dynamic stress is very important.

3). Take a notebook with you, the daily failure, how to exclude the process fo recording one by one, people's brains are long, easy to forget, good memory is better than rotten pen, recorded great benefits. We found that the injection moulding machine often some faults will repeat, and always these faults, as long as check how it was solved, in a few minutes can be troubleshooting, both fast and good. These things are as important as choose a injection machine.

Four, to think.

1). To think, to broaden their horizons and sometimes repair the injection machine cool enough, not well over analysis. We should put the alarm and fault conditions, comprehensive judgment from the outside to the inside, and screening, prediction of the maximum likelihood of failure, followed by exclusion. The end of hills and rivers have no doubt, there is away out, to think, to give you direction.

2). To think, to know why we are often in the exclusion of the injection molding machine fault, the reason sometimes did not find fault, after the fault and continue to occur.

3). According to the fault occurrence frequency, repeatability, mechanical and electrical life ahead, works conscientiously do a good job in spare parts. This is an important job to ensure the continuous and normal operation of the injection moulding machine. At the same time for some devices, with time delay, eliminated, the market has not buy or buy very expensive, be considered in advance, efforts to improve the external environment of the injection machine, temperature, humidity, dust from several aspects to think of a way, by adding a power regulator, equipped with electric cabinet air conditioning small house and other measures to make the fault greatly reduce the injection moulding machine.

Five, we should practice more, that is more practice.

1). To practice, to dare to do, good at work for the maintenance staff of injection molding machine, to be bold but cautious, dare to do, can only speak, do not, fix the injection molding machine. But to mature, then don't blindly, otherwise it will expand the failure, resulting in accidents, the consequences will be unimaginable, At the same time, we must also be good at hands-on, first of all, the machine should be familiar with the operation of the injection machine panels and the contents of the menu, operate freely. At the same time, it is necessary to make full use of the self diagnosis technology of the injection molding machine to deal with the faults quickly. Now the development of China injection machine, it is more and more strong ability of self diagnosis.

2). To practice more, to develop their own practical ability and to master the experimental skills, and sometimes some injection molding machine fault looks very vague, it is not clear whether the electrical fault or mechanical failure, we adopted the "separation method". There are many other methods to completely separate control of the electrical part and the original circuit, such as isolation and replacement method and comparative method, tapping method can be used as an effective means to help us find and eliminate the fault.

3). To practice, learn to use the instrument such as oscilloscope, millimeter, online detection circuit, short circuit tester, computer programmer etc. Can help us to judge and check the specific circuit, especially PLC, computer programmer, skilled use, free parameters can be input and output of plastic injection moulding machine, online test state. System initialization is helpful for analyzing faults, especially complex faults and solving problems.

4). To practice. "small leather" often occurs during the normal operation of a damaged element (such as switched, buttons, relays etc.) and no spare parts, repair yourself as much as possible or with special temporary bonding with other methods, the injection function of normal work, wait for spare parts after recovery.

5). To practice more, to do it yourself, generally speaking, injection molding machine circuit board can be good, the failure rate is very low, generally go to check the machine, do not doubt the board first. It can be eliminated by trial and error, initialization, hot and cold start, PLC and other methods. If it does prove a circuit board problem, fix it. These boards (usually no drawings) expensive, so the high speed injection moulding machine circuit board is very important, once the circuit board damage and no spare parts, and temporarily repaired, will inevitably stop, seriously affecting production. Sometimes, just a small circuit board fault, as long as the serious examination, it is not difficult to find problems, we have repeatedly found that individual capacitor leakage, board weld, short circuit fault, some circuit board is more complex, but as long as the time, through the inspection instruments, but also is to fix the circuit board. But there are some situations seriously, especially the large scale integrated circuit, difficult maintenance, plus the original devices, spare parts, can only but or send out early prepared plate repair. DIY repair board, is of great benefit, one can save cost for enterprise, on the other hand can solve as pressing danger, "dissecting a sparrow" familiar with electronic circuit analysis, training their own judgment and ability is very useful.

You may also like:

- Basic knowledge of injection molding machine

The injection molding machine (IMM) is one of the most significant and rational forming methods existing for processing plastic materials. For example, in PET packaging area, preform in...

- How to find a good PET injection machine manufacturer in China?

China as the world factory, there are so many different preform injection machine manufacturers. So, how to choose the right injection machine maker here is very difficult but important...

- The FAQs about our bottle preform injection machines

What is the advantage of servo hydraulic system? 1.Independent electric screw drive brings you both melting and energy efficiency. 2.The whole hydraulic system is driven by servo...

- How to choose a injection machine?

Before you want buy a injection machine, you should know something first. We know, purchasing an injection molding machine is not a small investment, buying a too big machine is waste of m...

- Linear or Rotary… That is a Question!

Linear blow molding machine or Rotary blow moulding machine, what should I choose, that is a big question! Now, Tina will tell you the same and the difference of these two type. The sam...

Notice: The views expressed are my own and do not necessarily represent the views of DEMARK.

Copyright © 2013 - 2024 www.pet-machinery.com all rights reserved. Designed by Tina | Sitemap