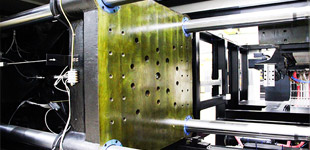

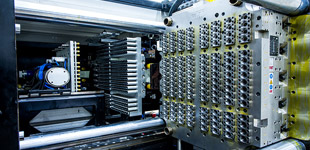

iPET Series High Speed Preform Injection Machine

High world class high performance PET preform production injection system

Demark iPET high speed preform injection machine allows you gain the same level of specification as European machine but with lower investment cost at the same time. The injection molding machine have two robots, one is for cooling, another is for picking, can produce with the preform molds up to 144 cavities which including double screw design high speed injection machine precision preform injection molds, post cooling, take out robot, centralized control system and high efficiency material drying system. The results are higher production efficiency, and better preform quality. You can also choose MHT preform injection molds from Germany at the same time.

Demark also insist on the "turnkey" solution concept by offering preform design and whole plant planning to our customers with more suggestion on various aspect to help our customers keep long term competitive strength in the hyper competitive, changeful consuming market.

Video

Technology

Electric screw drive

Independent electric screw drive brings you both melting and energy sfficiency.

Synchronous melting

Synchronous material melting, plasticization and injection at the same.

Reliable mold-locked

The template structure specially designed for PET preform mold is that all parts of the die are uniformly stressed, while ensuring the requirements of high-speed die opening and closing die.

Post cooling take out robot

The double stage post cooling robot makes the preform perfectly cooled with better cycle time.

THK linear guide

With the optimized PET special hinge parameters, the opening and closing die is fast and stable.The second board and the pull rod are completely disengaged, and the second board is supported by THK linear guide, which has samll resistence and saves energy.

High efficiency accumulator

Up to 5 sets of high efficient accumlator ensure the stability of high capacity injection.

Servo valve control

Advanced servo valve control technology makes the highly dynamic injection possible.

HCI control system

BECKHOFF centralized control system special designed for PET production, and run well on our PET preform injection machines.

Highlights of PCI control system

-

Stable and fast cycle time.

-

Fast PLC execution time.

-

High performance PC and fastI/O capability.

-

Quick communication thought all control components.

-

Self-adjustment and self-adaption.

-

High level control algorithm for speed, pressure and temperature. High level control strategy for reducing energy consumption.

-

Friendly user interface design.

-

Intuitive icon design for fast learning and control.

-

Fast information reading by press less buttons.

-

Single function button design.

-

Clear and accuracy alarm function.

-

Detailed event log.

-

15 Inch touch screen, 2.1G dual core CPU, 3GB memory and 80G hard drive equiped.

-

No touched electronic ruler with longer life time, and EtherCat digital single with stronger anti-interference capability.

Main technical features

| Item | Unit | iPET300 / 3500 | iPET300 / 5000 | iPET400 / 5000 | iPET400 / 6000 | iPET500 / 7000 |

| Screw L/D Ration | L/D | 25 | 25 | 25 | 25 | 25 |

| Screw Diameter | mm | 100 | 120 | 120 | 130 | 140 |

| Shot Weight (PET) | g | 3500 | 5000 | 5000 | 6200 | 7200 |

| Plasticizing (PET) | g/s | 200 | 300 | 300 | 380 | 470 |

| Clamping force | T | 300 | 300 | 400 | 400 | 500 |

| Clamping Stroke | mm | 585 | 585 | 670 | 500 | 550 |

| Max/Min Thickness of mold | mm | 300 - 720 | 300 - 720 | 300 - 820 | 500 - 1300 | 550 - 1350 |

| Space Between Tie Bars (W*H) | mm | 660 * 760 | 660 * 760 | 845 * 845 | 920 * 920 | 1020 * 1120 |

| Ejector Stroke | mm | 180 | 180 | 180 | 200 | 200 |

| Ejector Force | T | 20 | 20 | 28 | 41 | 51 |

| NO.of Ejector Pins | pcs | 9 | 9 | 13 | 10 | 10 |

| Cavity(Max) | pcs | 72 | 72 | 96 | 128 | 144 |

| Type of Mould | Needle Valve of Non-cutting PET Preform Mould | |||||

| Pump Moter Power | kw | 81+82 | 81+82 | 81+82 | 110+130 | 130+130 |

| Robot Power | kw | 36 | 36 | 43 | 108 | 108 |

| Heater Input Capacity | kw | 78 | 86 | 86 | 130 | 130 |

| Mould Heater Capacity | kw | 55 | 55 | 68 | 90 | 90 |

| Manipulator | Cavity | 216 | 216 | 288 | 384 | 432 |

| Cooling Form | Cavity | 216 | 216 | 288 | 384 | 432 |

| Size(L*W*H) | cm | 263 * 157 * 230 | 263 * 157 * 230 | 281 * 160 * 250 | 315 * 260 * 273 | 315 * 260 * 273 |

| Power Supply (3-phase AC) | V/HZ | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 |

| kw | 332 | 332 | 360 | 568 | 568 | |

| Chilling Water | ℃ | 5-10 | 5-10 | 5-10 | 7-9 | 7-9 |

| Mpa | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | |

| L/Min | 900 | 900 | 1200 | 1200 | 1200 | |

| Cooling Water | ℃ | <25 | <25 | <25 | <25 | <25 |

| Mpa | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |

| L/Min | 300 | 300 | 300 | 300 | 300 | |

| Compressed Air | Mpa | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 |

| L/Min | 800 | 800 | 1200 | 1200 | 1200 | |

| Machine Size (L*W*H) | cm | 930 * 180 * 250 | 990 * 180 * 250 | 1090 * 205 * 260 | 1180 * 250 * 270 | 1240 * 270 * 300 |

| Machine Weight | T | 26 | 28 | 34 | 39 | 44 |

|

Notice: Demark reserve the rights to make any product improvement or specification change without prior notice.

|

||||||

Downloads

Brochure: iPET Series Preform Injection Machine (PDF - 1.09 MB)

Notice: The views expressed are my own and do not necessarily represent the views of DEMARK.

Copyright © 2013 - 2024 www.pet-machinery.com all rights reserved. Designed by Tina | Sitemap