Blow molding process VS injection molding process

Blow molding a very popular manufacturing process which widely used in liquid packaging, such as plastic bottle, mineral water bottles, cosmetic bottles, drink bottles, plastic jug, plastic jar, etc. It starts from the 1930s, although till now this technology has already had a wide range of applications. Blow molding is used to create hollow plastic parts by inflating a heated plastic tube until it fills a mold and forms the desired shape. The raw material in this process is a thermoplastic in the form of small pellets or granules, which is first melted and formed into a hollow tube, called the parison. There are various ways of forming the parison, as explained below. The parison is then clamped between two bottle blowing mold halves and inflated by pressurized air until it conforms to the inner shape of the mold cavity. Lastly, when the plastic products has be cooled, the blowing mold will be separated and the products are ejected.

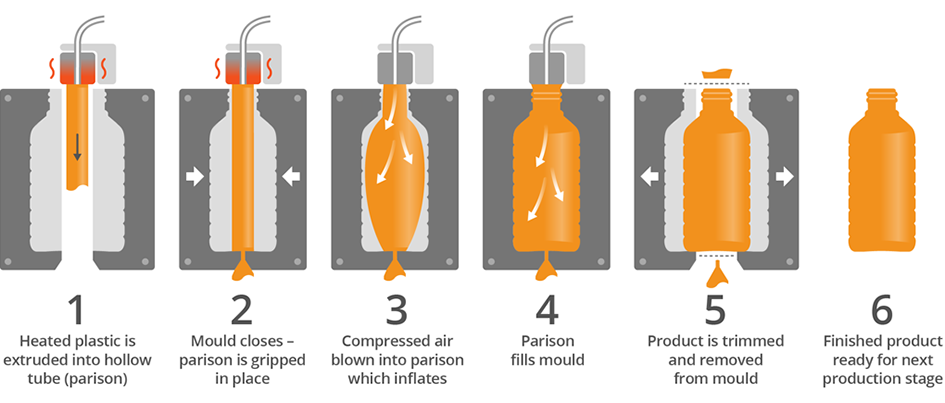

There are 6 steps for blow molding process. 1. Heated plastic is extruded into hollow tube (parison). 2. Mould closes-parison is gripped in place. 3. Compressed air blown into parison which inflates. 4. Parison fills mould. 5. Product is trimmed and removed from blowing mould. 6. Finished product ready for next production stage.

Now, you can look at the picture below learn about the production of the plastic bottle. It will greatly help you understand the blow molding process.

Injection molding is a method to obtain molded products by injecting the plastic materials molten by heat into a plastic mold, and then cooling and solidifying them, the. It is one of the very important technology for processing plastic. The raw material can be PE, PET, PP, PVC, PS, ABS, PMMA, POM, PC, PA etc.

The method is completely suitable for the mass production of products with complicated shapes, and takes a large part in the area of plastic processing, such as aviation, aerospace, electronics, machinery, ship and automobile industries. In addition, it is widely used in our daily life, the most common samples are plastic household products and liquid packaging bottles.

The process of injection molding is divided into 6 major steps as shown below.

1, Clamping 2. Injection 3. Dwelling 4. Cooling 5. Mold opening 6. Removal of plastic products.

The whole injection molding process is proceeded as shown below and products can be made successively by repeating the cycle.

You may also like:

- Basic knowledge of injection molding machine

The injection molding machine (IMM) is one of the most significant and rational forming methods existing for processing plastic materials. For example, in PET packaging area, preform in...

- Maintenance experience of injection molding machine

Injection molding machine is a mechanical, electronic control, hydraulic integration crystallization, electrical complex, oil pressure pipeline crossing buildings, all kinds of products...

- Troubleshooting guide of plastic injection molding

Injection molding is a process of shaping plastic by melting it and injecting it into a predesigned mold. The process was first designed in the 1930s and was originally based on metal d...

- What is stretch blow molding process?

Nowadays, the Blow Molding Machinery Manufacturing industry has a moderate level of capital intensity. In addition to acquiring, maintaining and updating specialized technical equipment...

- Three kinds of blow molding machine

For blow molding machine area, three kinds of blow molding machine take over the market: injection blow molding, extrusion blow molding, and stretch blow molding. Regula...

- Linear or Rotary… That is a Question!

Linear blow molding machine or Rotary blow moulding machine, what should I choose, that is a big question! Now, Tina will tell you the same and the difference of these two type. The sam...

Notice: The views expressed are my own and do not necessarily represent the views of DEMARK.

Copyright © 2013 - 2024 www.pet-machinery.com all rights reserved. Designed by Tina | Sitemap