Blow mould material

Compared with PET preform mold, blowing mould suffer comparatively low clamping and blow pressure, so it need not be made of a high tensile strength strength material, exception that for long production, say, hundreds of thousands or millions, which are sometimes made of steel. The main raw material for blow moulds are made from aluminum billet, cast aluminum alloys, zinc alloys.

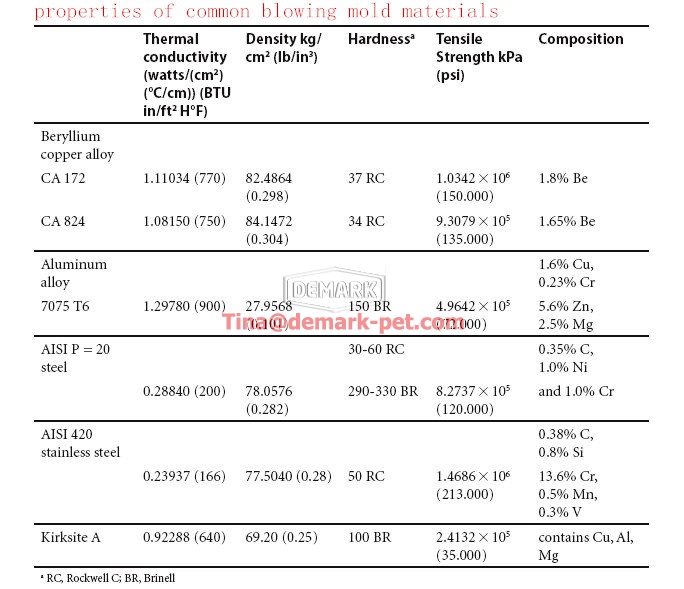

Pinch inserts or cores where rapid heat transfer is needed always made of beryllium copper because of expense and difficulty in machining. All these alloys are best for blow molds.

Aluminum is the softest mold materials in use and most easily damaged in the shop. What’s more, aluminum molds wear easily. Third they are easiest to machine. Aluminum and beryllium copper cast molds may be porous, sometimes blow molders have experienced some permeability of molds to resin. It may have an influence of the blown part. The way to solve the problem is coating the inside of themold halves with a sealer. By doing this, it will not affect heat transfer between the resin blown against blowing mold and mold walls.

Molds made of steel are heavier, more expensive and difficult to machine than that made of nonferrous alloys. In heavier weight mean more setup time in the molding shop. Second, the heat conductivity of steel is inferior to that of nonferrous mold material. It leads to a slower cooling rate and correspondingly longer cooling cycle and consequently, a low production rate for steel molds.

You may also like:

- What is stretch blow molding process?

Nowadays, the Blow Molding Machinery Manufacturing industry has a moderate level of capital intensity. In addition to acquiring, maintaining and updating specialized technical equipment...

- Bottle blowing process

Before buying a bottle blowing machine ,you must know how the preform becomes bottle first. Based on PET BOTTLE produced by TWO STEP automatic stretch blow molding machine. ...

- How to choose a PET bottle blow molding machine?

How to buying a blow moulding machine can be a nerve racking experience for the fresh entrepreneurs. The PET bottle blow molding machine price is a secondary consideration. There countl...

Notice: The views expressed are my own and do not necessarily represent the views of DEMARK.

Copyright © 2013 - 2024 www.pet-machinery.com all rights reserved. Designed by Tina | Sitemap